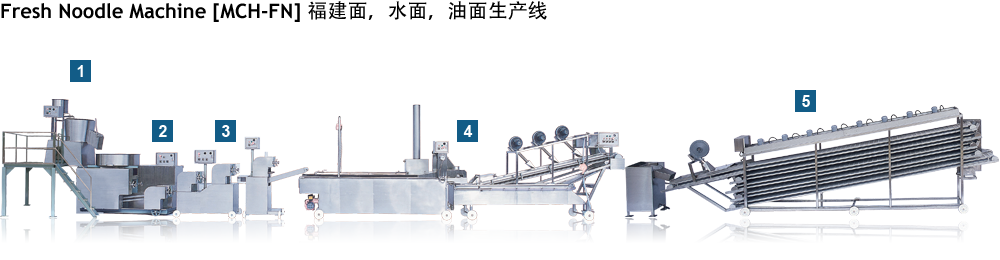

| 1 | Flour Mixer [MCH-MX] |

|

Wide selections of premium grade stainless steel flour mixer are available, ranging from small scale 10kg vertical flour mixer to high capacity 150kg horizontal flour mixer. The design of vacuum flour mixer is an ideal alternative for those who wish to improve the cost factor in food production.

Vertical Flour Mixer: 10 – 75 kg |

|

| 2 | Compound Dough and Sheet Presser [MCH-GN] |

|

This heavy duty compound dough sheet pressing machine is capable of processing up to 300kg of compound dough and transform it into thick layer of dough sheet. High durability and consistent performance. Dough Sheet Width: 10 – 24 inch Option: Flat Roller, Wavy roller |

|

| 3 | Sheet Presser [MCH-GN] & Fresh Noodle Former [MCH-FN] |

|

Equipped with dough sheet tension auto adjustment sensors, these sheet pressers are fully self-sustaining with minimum monitoring. The modular design allows integration of multiple units of sheet pressers, into a seamless solution to produce fine layer of dough sheet. Single Sheet Presser: 10 – 24 inch Continuous 2-in-1 Sheet Presser: 10 – 24 inch Continuous 3-in-1 Sheet Presser: 10 – 24 inch Option: Flat Roller, Wavy Roller, extension conveyor, powder duster These versatile noodle formers are capable to produce various type of oriental noodle of different size. The carefully fabricated noodle cutters are not just accurate and durable; it is exchangeable as easy as plug and play. Fresh Noodle Former: 10 – 24 inch Wonton Noodle Former: 8 – 18 inch Dried Noodle Former: 10 – 22 inch Stick Noodle Former: 10 – 12 inch |

|

| 4 | Noodle Cooker [MCH-GN] & Noodle Washer [MCH-GN] |

|

This is a fully automated noodle cooker capable of processing large volume of noodle using its continuous noodle transferring system, made possible by premium grade stainless steel roller chain and wire mesh. It is designed for easy cleaning and adjustable temperature control. Effective width: 12 – 26 inch Tank Length: 10 – 20 ft Option: Diesel Burner, Steam heating, dual system The noodle washer not only washes away the residue starch found in the cooked noodle, it also cools the noodle significantly to restore the smooth texture and elasticity of the noodle being produce. Effective width: 14 – 30 inch Tank Length: 12 – 15 ft |

|

| 5 | Multi-tier Cooler and Slackener [MCH-FN] |

|

Designed to accommodate minimum foot print, these multi-tier cooler are capable to cool down and dry off excessive water from the cooked noodle. The add-on slackening process prevents compounding of sticky noodles. Effective width: 16 – 32 inch Tank Length: 12 – 20 ft Option: 3-tiers, 5 tiers, 7 tiers |

|